What material is better for rice vacuum packaging bags?

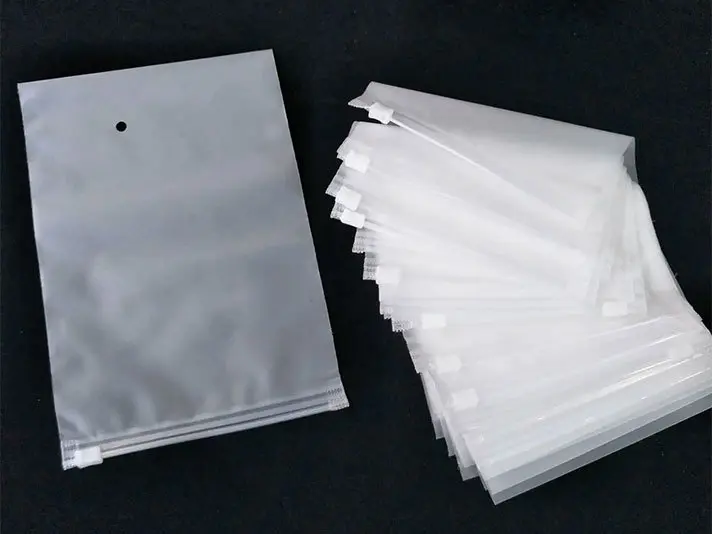

Vacuum packaging bags can serve as moisture and oxygen barriers, effectively extending the shelf life of food. With the improvement of people's quality of life, rice has also joined the ranks of vacuum packaging, and the material of vacuum packaging bags directly affects its effectiveness. So it is very important to determine the material when purchasing rice vacuum bags. So, what material is better for rice vacuum packaging bags?

1 PET: Polyester film has good mechanical properties and excellent printing effects.

2 Al: Aluminum foil film has good barrier properties, can block light, and is suitable for products that need to prevent light exposure;

3 PE: Polyethylene, a polymer formed by the polymerization of ethylene. Polyethylene is a typical thermoplastic with strong low-temperature resistance;

4 NY: Also known as nylon, vacuum bags made of this material are more stable during use, and the material is not affected by the surrounding environment. At the same time, NY material packaging bags are more sturdy and durable, and are not easily damaged or punctured even during long-term transportation and handling. To improve the performance of rice vacuum packaging bags, nylon composite materials are more commonly used, which can provide more convenient conditions for rice manufacturers' sales work.

The above introduction about the material of rice vacuum packaging bags is organized by Jinde Packaging. Jinde Packaging produces food vacuum packaging bags and rice vacuum packaging bags, with more than 10 years of industry experience accumulation. It has in-depth research on the selection of materials for vacuum packaging bags and can provide users with reasonable opinions to help them process ideal packaging bags. Hotline: 15902743510

中国

中国