The function and application of textured vacuum bags

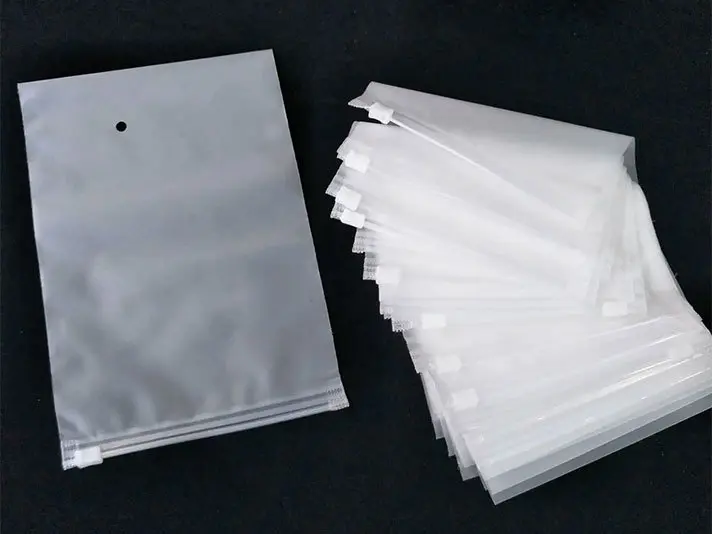

Pattern vacuum bag, also known as embossed bag, is a commonly used vacuum bag on the market. The surface of the textured vacuum bag has obvious mesh patterns or different patterns of patterns, which allows the bag to form microchannels during vacuum pumping, facilitating exhaust and making the bag surface more closely attached to the item. At the same time, these patterns can also increase the friction inside the bag, making it more tightly adhere to fragile or deformable foods such as fish, vegetables, etc., effectively preventing food from being squeezed and deformed during transportation.

The textured vacuum bag, as a specially designed vacuum packaging material, has multiple functions and a wide range of application scenarios. The following is a detailed introduction to the functions and applications of textured vacuum bags:

One function

- Excellent exhaust performance:

The textured design on the surface of the vacuum bag can form microchannels for easy exhaust. During the vacuum pumping process, these microchannels can guide air to be quickly expelled, creating a negative pressure environment inside the bag and effectively preventing food oxidation and spoilage.

- Tight adhesion:

The pattern design increases the friction inside the bag, allowing it to adhere more tightly to the packaged items and prevent them from being deformed or damaged due to compression during transportation or storage.

- Good sealing:

The textured vacuum bag uses high-quality sealing materials, carefully designed and manufactured to ensure good sealing performance after sealing, preventing air and moisture from entering the bag and extending the shelf life of food.

- Diversified appearance:

The surface of the textured vacuum bag can be customized with different patterns and colors according to customer needs, meeting consumers' personalized needs for product appearance.

II application

- Food industry:

Pattern vacuum bags are widely used in the food industry, especially for foods that require long-term storage or transportation, such as meat, fish, vegetables, fruits, etc. Vacuum packaging can effectively extend the shelf life of food, maintain its freshness and taste.

- Electronic industry:

In the electronics industry, textured vacuum bags are also commonly used to package sensitive items such as electronic components and circuit boards. Through vacuum packaging, it is possible to prevent damage to electronic components caused by static electricity, moisture, etc., ensuring the quality and reliability of the product.

- Pharmaceutical industry:

The pharmaceutical industry has very strict requirements for packaging materials, and textured vacuum bags are highly favored for their excellent sealing and sterility. It is widely used for packaging drugs, medical devices, etc. to ensure the safety and effectiveness of products.

- Other industries:

In addition to the above-mentioned industries, textured vacuum bags are also used in various other fields, such as textiles, handicrafts, hardware products, etc. By vacuum packaging, these items can be protected from environmental factors such as dust and moisture, improving product quality and market competitiveness.

In summary, textured vacuum bags have multiple functions and a wide range of application scenarios, making them an indispensable packaging material in the modern packaging industry. When choosing textured vacuum bags, the selection should be based on specific application scenarios and requirements to ensure the quality and effectiveness of the product.

中国

中国