Production process of vacuum rice brick bags

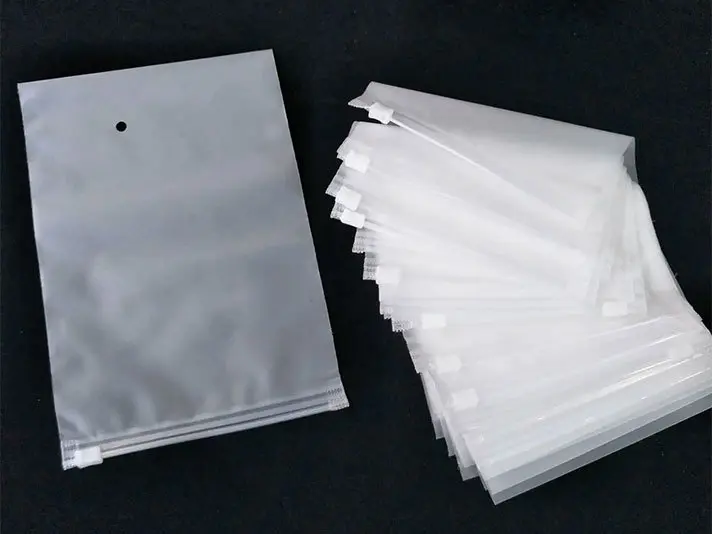

Vacuum rice brick bag is a packaging bag specifically used for storing and transporting rice. Through vacuum sealing technology, the air inside the bag is extracted to form a vacuum state, effectively preventing rice from being affected by external factors such as moisture and oxidation during storage and transportation. The opening of the vacuum rice brick bag is usually designed to be easy to tear, making it convenient for consumers to easily open the packaging and take out the rice. In addition, some vacuum rice brick bags are also equipped with a handheld design for easy handling and storage.

The production process of vacuum rice brick bags is a complex and delicate process aimed at ensuring the safety, durability, and sealing performance of packaging materials. The following is the main production process of vacuum rice brick bags:

1、 Material selection and preparation

Film material: Plastic films such as polyethylene (PE), polypropylene (PP), or nylon (PA) are selected as the main materials. These materials need to have good barrier properties, mechanical strength, and heat sealing performance.

Additives: Add antioxidants, anti UV agents, and other additives to the film material as needed to improve its stability and service life.

2、 Printing and bag making

Printing: Printing necessary information such as product name, brand logo, production date, shelf life, etc. on the surface of the film. The printing process needs to ensure the food safety and good adhesion of the ink.

Bag making: By heat sealing or bonding, thin films are made into bags with specific shapes and sizes. During the bag making process, it is necessary to ensure the dimensional accuracy and sealing performance of the bag.

3、 Measurement and Filling

Measurement: Use automatic measuring equipment to measure rice and other food according to the predetermined weight.

Filling: The measured rice is fed into a vacuum rice brick bag through a filling equipment. During the filling process, it is necessary to ensure that the rice is evenly filled to avoid gaps.

4、 Vacuum sealing

Vacuuming: Place the bag containing rice in the vacuum chamber of the vacuum sealing machine, start the vacuum pump, and extract the air inside the bag.

Sealing: While vacuuming, heat seal the bag to ensure it is sealed under vacuum. During the sealing process, it is necessary to control the heat sealing temperature and pressure to avoid bag damage or poor sealing.

5、 Quality Inspection and Packaging

Quality inspection: Conduct inspections on the appearance quality, sealing performance, weight deviation, and other aspects of the vacuum rice brick bags produced. Ensure that each bag meets relevant standards and requirements.

Packaging: Pack the vacuum rice brick bags that have passed the inspection in a fixed quantity for easy transportation and storage. During the packaging process, it is necessary to ensure that the bags are not squeezed or damaged against each other.

6、 Storage and transportation

Storage: Store the packaged vacuum rice brick bags in a dry, cool, and well ventilated warehouse, avoiding direct sunlight and high temperature environments.

Transportation: During transportation, it is necessary to ensure that the empty rice brick bag is not subjected to physical damage such as compression or impact, while maintaining a vacuum state inside the bag.

In summary, the production process of vacuum rice brick bags includes multiple stages such as material selection and preparation, printing and bag making, measurement and filling, vacuum sealing, quality inspection and packaging, as well as storage and transportation. Each stage requires strict quality control to ensure the safety and reliability of the product.

中国

中国