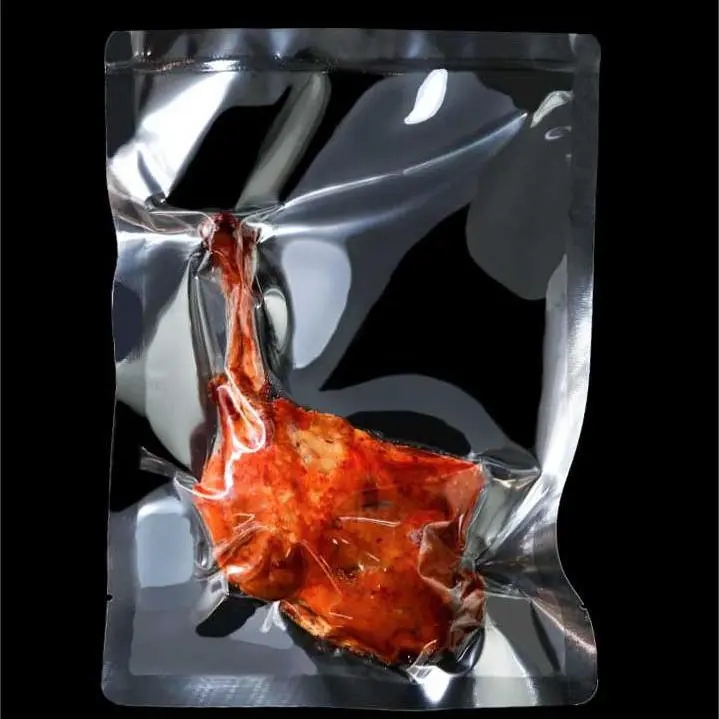

Custom Printed High Temperature Retort Bag Sterilized Aluminum Foil Bag for heating and cooking food

APPLICATION

Retort bag is a special type of bag used for heating and cooking food. It has a wide range of uses and is especially suitable for prepared foods, such as rice, noodles, vegetables, soup and meat.

Features

A. High temperature resistance. It can withstand the high temperature and pressure during the cooking process without rupture or deformation.

B. The material of the bag is usually food grade plastic, which is non-toxic, odorless, safe and hygienic.

C. It can be directly put into the steamer or microwave oven for heating without additional containers, pots and pans.

D. With good sealing performance, it can effectively keep the moisture and nutrients of food while avoiding contamination and food oxidation.

Key attributes

| Product Name | Retort bag |

| Bag Type | Stand-up pouch, flat bottom pouch or customized |

| Application | Packaging for prepared foods, such as rice, noodles, vegetables and meat. |

| Certificates | ISO9001, ISO14001, ISO45001, FSSC22000, HALAL, SGS and TUV |

| Surface Handling | Gravure printing |

| Material Structure | BOPET/AL/PE, BOPET/PE, BOPET/VMPET/PE, BOPET/BOPA/RCPP, BOPET/AL/RCPP, or Customized |

| Samples | Free sample or negotiated without freight paid |

| Sealing&Handle | Zipper top |

| Size | Customized |

| Color | Up to 10 colors |

| Thickness | 15-200 microns |

| MOQ | 10000PCS: mainly depends on the bag size and printing artwork |

| Production Flow | Film blowing-printing-lamination-slitting-bag making |

| Terms of Payment | T/T, L/C or per negotiate |

| Lead Time | 15-30 days or as per negotiated |

| Incoterms | EXW, FOB, CFR, CIF, DDP etc |

Product advantages

● Retort bag produced by Jinde Packaging is resistant to high temperatures of 121 ° C and is suitable for back pressure sterilization pots.

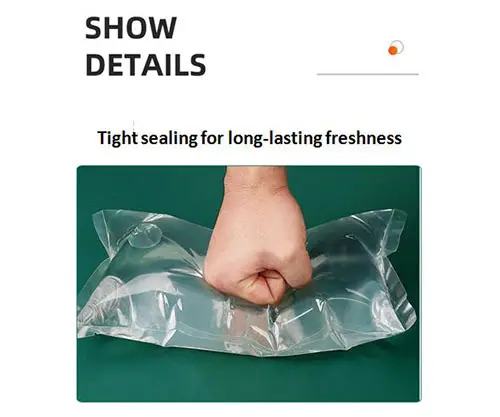

● Retort bag/high-temperature boiling bags produced by Jinde Packaging has the characteristics of tight sealing and longer preservation.

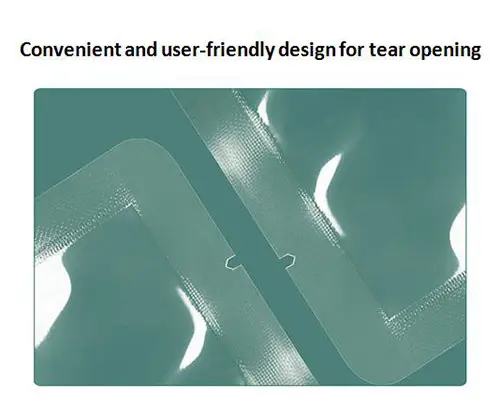

● Retort bag/high-temperature boiling bags produced by Jinde Packaging adopts a convenient and user-friendly design for tearing.

● Retort Bag/high-temperature boiling bags produced by Jinde Packaging adopts a rounded design, which is more exquisite.

● Retort Bag/high-temperature boiling bags produced by Jinde Packaging adopt RCPP material which is a PP-based sealant film with excellent heat resistance that is specially formulated for retort applications.

Product Encyclopedia

Product structure

In order to meet the requirements of retort bag/high-temperature boiling bags, the outer layer of the structure is selected with high strength polyester film, the middle layer is selected with aluminum foil with light shielding and air tightness, and the inner layer is selected with polypropylene film. Three layer structure are PET/AL/CPP and PET/PA/CPP, four layer structure are PET/AL/PA/CPP.

Physical property parameters

It includes CPP ordinary cooking film (120℃) and high temperature cooking film (135℃), it has high temperature dimensional stability and other material compliance features, high temperature heat seal strength retention is good. The thickness is generally 60-80um.

Below as example: Typical values of product physical properties are shown in the table.

Typical physical properties of products (ASTM standard, heat seal strength standard is TAPPI683)

| Thickness | Tensile strength (MPa) | Elongation at break (%) | Heat Shrinkage % (120℃ 5min) | Right Angle Tearing strength (N/mm) | ||||

| - | MD | TD | MD | TD | MD | TD | MD | TD |

| 70um | ≥40 | ≥25 | ≥450 | ≥500 | ≤1.0 | ≤1.5 | ≥100 | ≥150 |

| Friction coefficient | Thickness range(%) | Average thickness Deviation (%) | Fog degree(%) | Glossiness(%) | Corona treatment strength(mN/m) | Heat seal strength(N/15mm) | |

| Inner/Inner | Out/Out | ≥±5.0 | ≥±1.2 | ≥ 4.0 | ≤75 | ≤ 38 | ≤8.0 |

| ≥0.60 | ≥0.20 | ||||||

FAQ

Q: Are you trading company or manufacturer?

A: We are a competent manufacturer in China specializing in plastic film making, color-printing and laminating flexible packaging, we focus on food packaging, pet food packaging, personal care packaging etc.

Q: Do you provide samples ? Is it free or extra cost?

A: Yes, we could offer the sample. Free sample or negotiated without freight paid.

Q: Do you have any MOQ limit for order?

A: Our MOQ is 10,000 square meters for films.

Q: What information do you need to get a full quotation?

A: (1)Bag type(or drawing);

(2)Material Structure(single layer or laminated material);

(3)Detail specification;

(4)Thickness(for each layer material);

(5)Printing colors;

(6)Quantity.

Q: What makes you different in the packaging industry?

A: We are full chain production line factory, we make CPP /CPE/PE film by our own factory, with BOBST high speed printing machine, and Nordmaccanica lamination machine.

Our company is equipped with most advanced ERP system for management, which can result in significant cost savings and increased efficiency.

中国

中国