Custom Food Grade Resealable Bag Zip Lock Ziplock Bag Zipper Pouch for Packaging with Logo

APPLICATION

Zipper Slider bags can be used to package a variety of food products, such as snacks, candies, dried fruits, cookies and so on. They can also be used to package liquid food products such as juices, salad dressings and so on.

Features

A. Adopting switchable design, it can be opened and closed repeatedly, which is convenient for consumers to access the food and keep the food fresh and hygienic.

B. Effectively prevent the entry of outside air, moisture and impurities, ensure the quality and taste of food, and extend the freshness period of food.

C. It can be reused many times to reduce the impact on the environment and improve the utilization of resources.

D. Smaller size and light weight, easy to store and carry, convenient for consumers to enjoy food at any time in outdoor or traveling.

Key attributes

| Product Name | Zipper Bag |

| Bag Type | Stand-up pouch or customized |

| Application | Packaging for snacks, candies, dried fruits, cookies |

| Certificates | ISO9001, ISO14001, ISO45001, FSSC22000, HALAL, SGS and TUV |

| Surface Handling | Gravure printing |

| Material Structure | BOPET/AL/PE, BOPET/PE, BOPET/AL/CPP, BOPP/CPP, BOPP/PET/PE, or Customized |

| Samples | Free sample or negotiated without freight paid |

| Sealing&Handle | Zipper top |

| Size | Customized |

| Color | Up to 10 colors |

| Thickness | 15-200 microns |

| MOQ | 10000PCS: mainly depends on the bag size and printing artwork |

| Production Flow | Film blowing-printing-lamination-slitting-bag making |

| Terms of Payment | T/T, L/C or per negotiate |

| Lead Time | 15-30 days or as per negotiated |

| Incoterms | EXW, FOB, CFR, CIF, DDP etc |

Product advantages

● Jinde Packaging Company is a zipper bag manufacturer that supports various customized specifications of sealed zipper packaging bags, including three sides, eight sides, self-supporting, and middle sealing.etc.

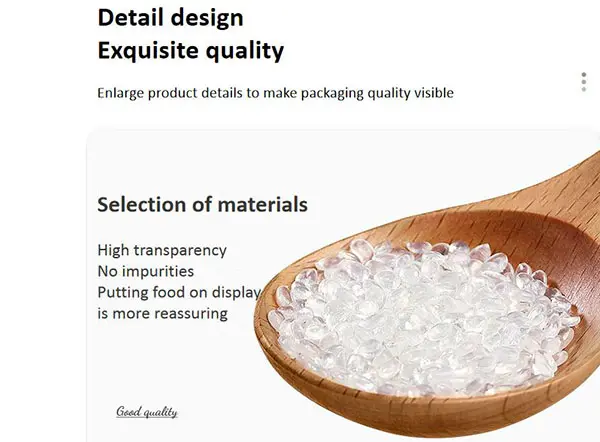

● Jinde Packaging Company carefully selects materials and designs thoughtful details. The zipper bags we produce are of exquisite quality, with high transparency, no impurities, and more reassuring when storing food.

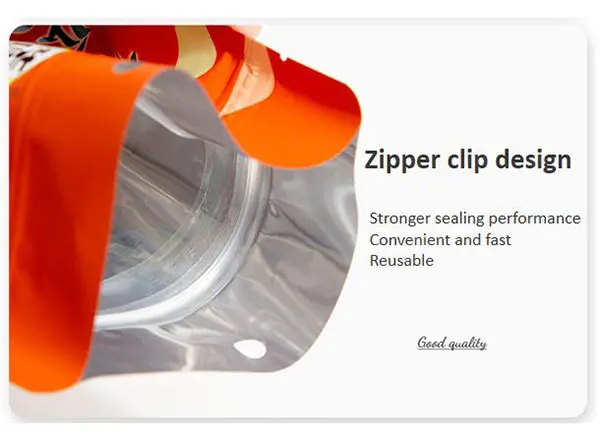

● The zipper bags produced by Jinde Packaging adopt zipper clip design, which has stronger sealing,convenience and secondary use.

● The zipper bags produced by Jinde Packaging have a thick bottom and adopt a standing design, which widens the bottom and makes standing more secure.

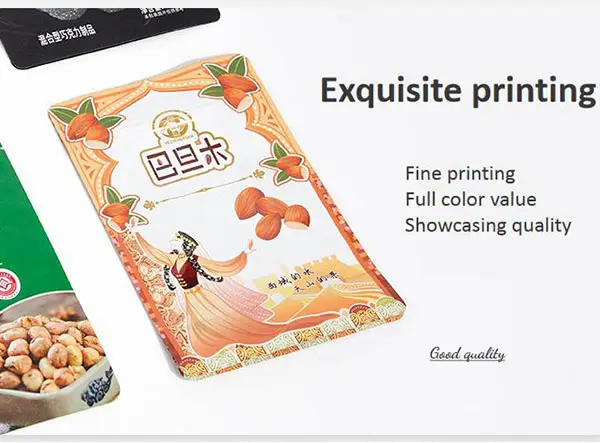

● The zipper bags produced by Jinde Packaging have delicate and exquisite printing, full color values, and showcase packaging quality.

Product Encyclopedia

The important index to evaluate the quality of zipper bag is the zipper opening force. If the flange and groove of the zipper are not closely matched, the opening force is slight, which will lead to poor air tightness of the zipper bag, and reduce the barrier property, also easy to leak, which has no protective effect; If the convex edge and groove are too tight, it will cause the opening of the zipper bag become difficult, and even the plastic film on both sides of the zipper bag will be stretched and deformed, affecting the convenience of the use of the zipper bag.

1, zipper bag features

The main feature of PE zipper bag is its tight seal and leak-proof design. This design allows the PE zipper bag to effectively protect the item, preventing air, moisture and other external factors from entering the bag, thus maintaining the freshness and quality of the item. In addition, PE zipper bags also have good durability and impact resistance, which can remain intact during transportation and use.

2. zipper bag use

PE zipper bags are versatile and can be used in a variety of different fields. In terms of food packaging, PE zipper bags are often used to package meat, seafood, fruits and vegetables and other foods, which can effectively maintain the freshness and taste of food. In addition, PE zipper bags are also often used in the field of personal care and beauty products, such as toothpaste, shampoo and cosmetics, to ensure the hygiene and quality of products. In the apparel sector, PE zipper bags can be used to store and protect items such as clothing, shoes and accessories from dust and dirt.

3. zipper bag advantages

PE zipper bags have many advantages that make them a popular packaging material. First of all, the PE zipper bag has excellent leak-proof performance, which can effectively keep the items dry and clean. Secondly, the PE zipper bag is easy to open and close, convenient to use and store items. In addition, PE zipper bags also have high strength and impact resistance, which can remain intact during transportation and use. Finally, PE zipper bags are affordable and easy to produce and process, so the cost is relatively low.

4. zipper bag production process

The process of producing PE zipper bags is not complicated and usually includes the following steps: First, the polyethylene material is blown after melting at high temperature; Then, the membrane is heat-sealed to form a bag; Next, attach a zipper to one end of the bag; Finally, the bag quality check and packaging. The production process needs to pay attention to the control of temperature, pressure and time to ensure that the produced PE zipper bag meets the quality requirements.

5. the future development of zipper bags

With the continuous improvement of people's awareness of environmental protection and the continuous progress of technology, the PE zipper bag industry is also constantly developing and improving. In the future, PE zipper bags will develop in a more environmentally friendly, sustainable and intelligent direction. For example: the development of degradable PE zipper bag materials, improve production efficiency and reduce costs, the application of Internet of Things technology to achieve intelligent management. The development of these technologies will bring broader market prospects and development opportunities for the PE zipper bag industry.

FAQ

Q: Are you trading company or manufacturer?

A: We are a competent manufacturer in China specializing in plastic film making, color-printing and laminating flexible packaging, we focus on food packaging, pet food packaging, personal care packaging etc.

Q: Do you provide samples ? Is it free or extra cost?

A: Yes, we could offer the sample. Free sample or negotiated without freight paid.

Q: Do you have any MOQ limit for order?

A: Our MOQ is 10,000 square meters for films.

Q: What information do you need to get a full quotation?

A: (1)Bag type(or drawing);

(2)Material Structure(single layer or laminated material);

(3)Detail specification;

(4)Thickness(for each layer material);

(5)Printing colors;

(6)Quantity.

Q: What makes you different in the packaging industry?

A: We are full chain production line factory, we make CPP /CPE/PE film by our own factory, with BOBST high speed printing machine, and Nordmaccanica lamination machine.

Our company is equipped with most advanced ERP system for management, which can result in significant cost savings and increased efficiency.

中国

中国