How to Choose the Right Plastic Film Roll for Food Packaging Based on Industry Standards

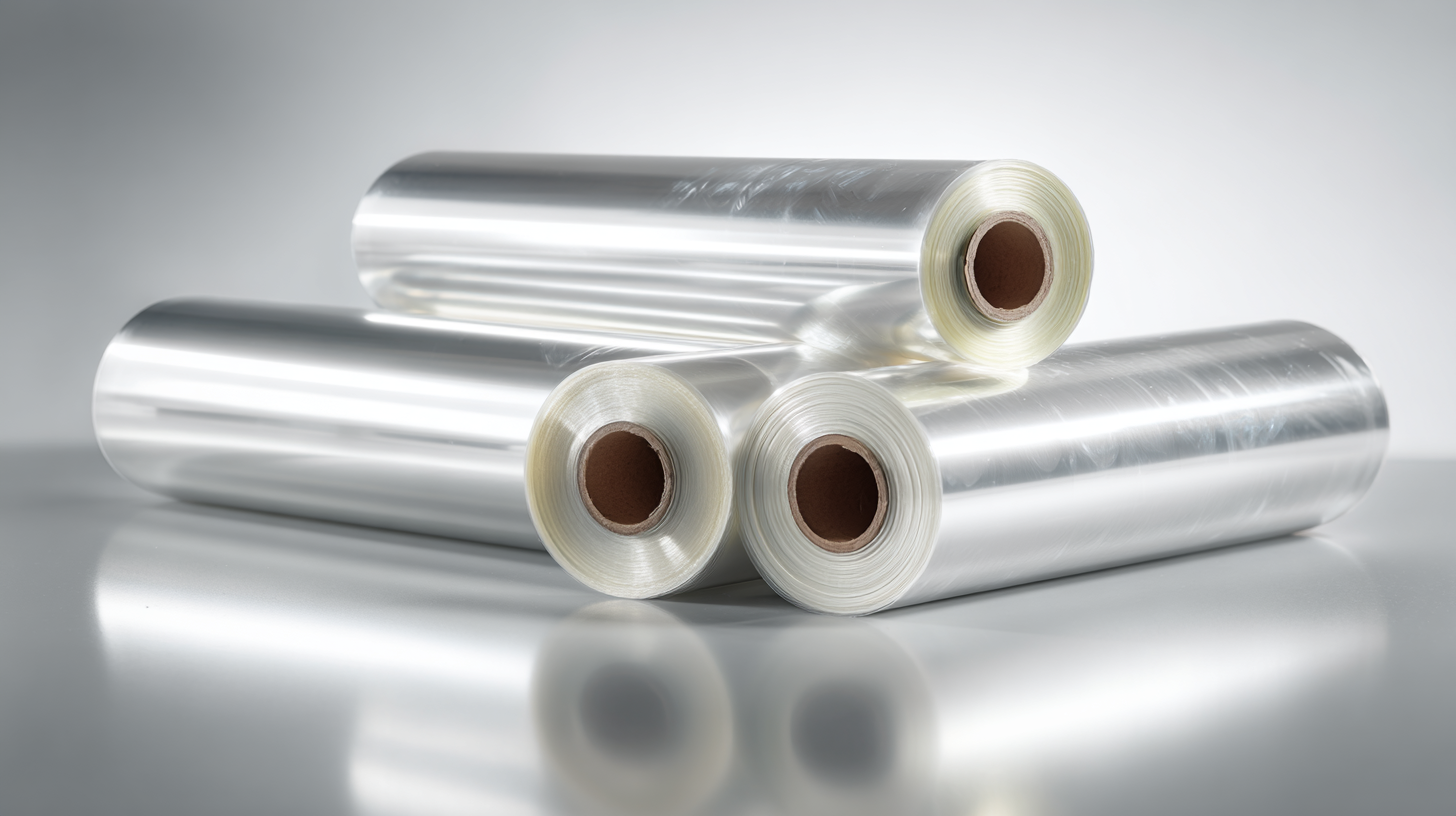

The selection of the appropriate "Plastic Film Roll For Food Packaging" is critical in ensuring product safety, extending shelf life, and adhering to industry standards. According to a report by the Food Packaging Forum, the global food packaging market is projected to reach USD 500 billion by 2027, with plastic films playing a crucial role in this growth due to their versatility and protective properties. In particular, the use of polyethylene and polypropylene films has increased, reflecting a demand for materials that provide effective moisture barriers and chemical resistance. Furthermore, the recent FDA guidelines highlight the importance of considering regulatory compliance and safety standards when choosing packaging materials. In a market where consumer safety and sustainability are paramount, understanding the different types of plastic film rolls available and their specific applications becomes vital for manufacturers aiming to maintain a competitive edge while meeting regulatory requirements.

Understanding Food Packaging Regulations and Standards

When selecting plastic film rolls for food packaging, understanding the relevant regulations and industry standards is crucial to ensure compliance and safety. The Food and Drug Administration (FDA) in the United States outlines specific guidelines for food contact materials, emphasizing the need for these materials to be safe, suitable, and not impart harmful substances to food. According to the FDA, any plastic film used in food packaging should be tested for migration levels, with permissible limits defined to prevent contamination and ensure consumer safety.

Moreover, the European Food Safety Authority (EFSA) provides a comprehensive framework for evaluating food contact materials. Their standards suggest rigorous assessments regarding the chemical composition and potential interactions with food. A report by the European Commission states that over 40% of food recalls are attributed to packaging issues, underlining the importance of adhering to these regulations. Compliance with these industry standards not only ensures product safety but also enhances consumer trust and brand reputation, critical factors for businesses operating in the competitive food sector. By staying informed and compliant with these standards, companies can better navigate the complexities of food packaging regulations.

Identifying the Right Type of Plastic Film for Different Food Products

When selecting the appropriate plastic film roll for food packaging, it’s essential to consider the specific type of food product being packaged, as different items have unique requirements for preservation and protection. For instance, products like fresh produce often require breathable films made from polyethylene to allow gas exchange, thus extending their shelf life. According to the Food and Agriculture Organization, improper packaging can lead to a staggering 30% of global food waste, underscoring the importance of utilizing the correct film type.

On the other hand, vacuum-sealed meats necessitate barrier films, such as multi-layer laminates, which help preserve freshness and prevent spoilage. A report by the Packaging Industry Association highlights that the demand for barrier protection in food packaging is projected to grow by 5.1% annually, driven by heightened consumer awareness regarding food safety and longevity. Therefore, identifying the right plastic film based on the food type not only enhances product quality but also plays a critical role in minimizing food waste throughout the supply chain.

On the other hand, vacuum-sealed meats necessitate barrier films, such as multi-layer laminates, which help preserve freshness and prevent spoilage. A report by the Packaging Industry Association highlights that the demand for barrier protection in food packaging is projected to grow by 5.1% annually, driven by heightened consumer awareness regarding food safety and longevity. Therefore, identifying the right plastic film based on the food type not only enhances product quality but also plays a critical role in minimizing food waste throughout the supply chain.

Evaluating Thickness and Durability Requirements for Food Safety

When selecting the appropriate plastic film roll for food packaging, one of the most critical factors to consider is thickness and durability, which directly impact food safety. According to the Plastics Industry Association, the thickness of packaging films typically ranges from 1.0 mil (0.001 inches) to over 6.0 mils, with thicker films often offering better puncture resistance and barrier properties. Reports indicate that films with a thickness of 2.0 to 4.0 mils are commonly used for perishable items, providing adequate strength to withstand mechanical handling while maintaining moisture and oxygen barriers.

Durability is equally essential, as food packaging must endure various environmental conditions, including temperature fluctuations and moisture exposure. The American Society for Testing and Materials (ASTM) emphasizes the need for materials to pass rigorous testing standards to ensure integrity under stress. A recent study highlighted that films with higher tensile strength, measured in pounds per inch (PLI), not only resist tearing but also provide better seal integrity. For instance, films with a tensile strength of 3,500 PLI or more are often preferred for heavy-duty applications, ensuring that packaged goods remain safe and fresh throughout their shelf life.

Assessing Heat Sealability and Barrier Properties in Plastic Films

When selecting plastic films for food packaging, it is crucial to assess their heat sealability and barrier properties, as these factors significantly impact the shelf life and safety of packaged products. Recent studies have highlighted the importance of using advanced materials with enhanced characteristics. For instance, the development of apple pectin-based active films has shown promising results in preserving oils, indicating that incorporating naturally derived compounds can improve functional properties. These films can effectively solubilize curcumin, which not only enhances the active qualities of the packaging but also increases its usability across various food products.

Moreover, the integration of bio-based materials such as cassia gum reinforced with cellulose nanocrystals has led to the creation of edible films that exhibit improved barrier properties and heat sealability. These films are not only an alternative to traditional plastics but are also aligned with sustainability trends in the packaging industry. Additionally, advancements in processing technologies, like ultrasound treatment on polyamide multilayer films, demonstrate a significant enhancement in performance when in contact with different food simulants. Ultimately, proper evaluation of these parameters will ensure that food packaging meets industry standards while contributing to environmental sustainability.

How to Choose the Right Plastic Film Roll for Food Packaging Based on Industry Standards - Assessing Heat Sealability and Barrier Properties in Plastic Films

| Film Type | Heat Sealability (℃) | Oxygen Barrier (cc/m2/day) | Moisture Barrier (g/m2/day) | Typical Applications |

|---|---|---|---|---|

| LDPE (Low-Density Polyethylene) | 120-160 | 250 | 1000 | Produce, Snacks |

| HDPE (High-Density Polyethylene) | 130-180 | 200 | 800 | Dairy, Frozen Foods |

| BOPP (Biaxially Oriented Polypropylene) | 150-190 | 150 | 500 | Dry Snacks, Bakery |

| PET (Polyethylene Terephthalate) | 160-220 | 50 | 300 | Meat, Cheese |

| PVDC (Polyvinylidene Chloride) | 150-200 | 20 | 200 | Processed Foods |

Choosing Eco-Friendly Options for Sustainable Food Packaging

Sustainable food packaging is increasingly becoming a priority for both consumers and manufacturers. With a significant rise in environmental awareness, choosing eco-friendly plastic film rolls has never been more critical. According to a recent report from Smithers PIRA, the global market for sustainable packaging is expected to grow at a CAGR of 5.7% from 2020 to 2025. This data underscores the importance of adopting materials that minimize environmental impact while still maintaining food safety standards.

One of the best tips for selecting eco-friendly plastic film is to look for certifications that validate sustainability claims, such as the Forest Stewardship Council (FSC) or the Biodegradable Products Institute (BPI). Also, consider films made from renewable resources, like PLA (polylactic acid), which is derived from corn starch and can compost under the right conditions. According to a study by the World Economic Forum, adopting biodegradable packaging could lead to a reduction in plastic pollution by up to 78 million tonnes annually.

Prioritizing recyclable materials is another essential tip. Ensure that the plastic film you choose is clearly marked for recycling, with appropriate disposal instructions, so consumers can easily participate in sustainable practices. Reports suggest that increasing recycling rates could drastically decrease the demand for virgin plastic, thereby lowering overall environmental footprints. Incorporating these strategies into your food packaging decisions can significantly contribute to a more sustainable future.

Related Posts

-

Global Leaders in Food Safety: Discover the Finest Plastic Rolls From China

-

Unlocking the Advantages of Plastic Roll for Food Packaging that Elevate Shelf Life and Safety

-

Maximizing Freshness and Safety with Innovative Plastic Roll for Food Packaging Solutions

-

Revolutionize Your Business with Premium Food Packaging Roll Plastic Film Solutions

-

Innovative Trends in Food Packaging Plastic Roll Market Driving Sustainability and Efficiency

-

China's Resilient Growth in Food Packing Solutions Amid US China Tariff Challenges

中国

中国