How to Choose the Best Food Packaging Plastic Roll for Your Needs

In the ever-evolving landscape of the food industry, the significance of

effective packaging cannot be overstated.

With the global food packaging market projected to reach approximately

$500 billion by 2027, as reported by Smithers Pira,

understanding the various options available, particularly in

Food Packaging Plastic Roll,

has become crucial for manufacturers and retailers alike. Plastic rolls

offer versatility, durability, and

cost-effectiveness, making them an essential choice for

preserving food quality while enhancing shelf appeal.

According to Dr. Jane Thompson, a leading expert in food packaging technologies,

"The right choice of food packaging material can

greatly impact both product safety and consumer satisfaction." This statement

underscores the importance of selecting high-quality

Food Packaging Plastic Roll that caters

to specific storage needs, regulatory standards, and sustainability

considerations. As businesses strive to meet consumer demands for fresh and

safely packaged products, focusing on the factors that influence the selection

of packaging materials can lead to better outcomes in the competitive food market.

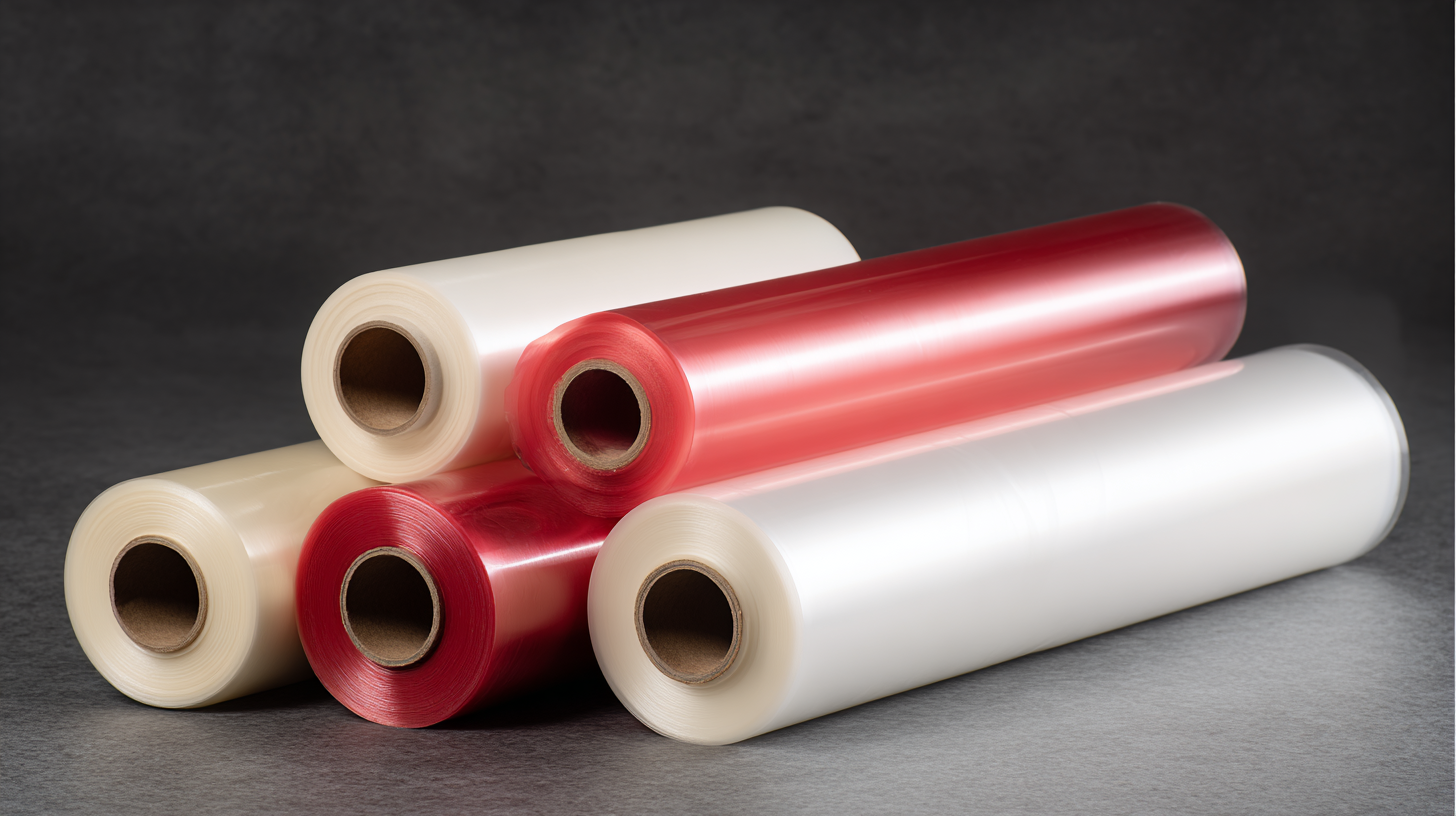

Understanding Different Types of Food Packaging Plastics: Key Features and Benefits

When selecting food packaging plastic rolls, it’s essential to understand the various types available, each with distinct features and benefits that cater to specific needs. Polyethylene (PE) is one of the most commonly used materials, known for its excellent moisture and chemical resistance. It is lightweight and flexible, making it an ideal choice for wrapping fresh produce and bakery items. On the other hand, Polyvinyl Chloride (PVC) offers superior clarity and sealing capabilities, making it perfect for packaging meat and cheese products, as it keeps the contents visible while extending shelf life.

**Tips:** When choosing the right plastic roll, consider the type of food you are packaging. For high-fat products, opt for materials like nylon, which provides a strong barrier against oxygen and moisture. Additionally, evaluating the thickness of the plastic is crucial. Thicker rolls typically offer better protection and durability, while thinner options are more cost-effective but might not hold up as well under pressure.

Another material to consider is Polypropylene (PP), prized for its high resistance to chemicals and temperatures. This makes it suitable for microwaveable containers as well as freezer-safe packaging. Look for options that are recyclable or made from recycled materials to ensure environmental sustainability while meeting your packaging needs.

Comparison of Different Types of Food Packaging Plastics

This chart illustrates the common uses of various types of food packaging plastics. PET is widely used, followed by HDPE and PP, while PVC and LDPE have lesser usage in food packaging due to other considerations.

Industry Trends: Market Demand for Eco-Friendly Food Packaging Solutions

The demand for eco-friendly food packaging solutions has surged significantly in recent years, propelled by growing consumer awareness and regulatory pressures. According to a report by Grand View Research, the global market for biodegradable packaging is expected to reach USD 414.95 billion by 2027, reflecting a compound annual growth rate (CAGR) of 5.7% from 2020. This shift indicates that consumers are increasingly favoring brands that prioritize sustainability in their packaging choices, prompting manufacturers to adapt their products accordingly.

Furthermore, a survey conducted by Nielsen revealed that 73% of global consumers are willing to change their consumption habits to reduce their environmental impact. This trend is particularly evident in the food industry, where there is a heightened focus on reducing plastic waste. As a result, companies are innovating with materials such as plant-based plastics and compostable films, which not only cater to the eco-conscious consumer but also help businesses comply with existing and upcoming regulations aimed at reducing plastic pollution. The emphasis on sustainable food packaging reinforces the importance of choosing packaging materials that align with both environmental goals and market demands.

Evaluating Thickness and Strength: How to Select the Right Gauge for Freshness and Safety

When selecting food packaging plastic rolls, evaluating the thickness and strength is crucial for maintaining freshness and ensuring safety. The gauge of the plastic, often measured in mils, indicates its thickness; the thicker the material, the more durable it typically is. For perishable items such as meats and produce, a thicker gauge can provide better protection against punctures and tears, which might otherwise lead to spoilage. A range of 2-4 mils is commonly recommended for these types of products, as it strikes a balance between flexibility for wrapping and sufficient strength for protection.

In addition to thickness, the strength of the plastic is important for maintaining the integrity of the packaging over time. Stronger plastic rolls can withstand varying temperatures and environmental conditions, which is particularly relevant for frozen or refrigerated goods. When choosing packaging, consider the specific needs of your food items—those that need extended shelf life or extra protection from contamination will benefit from stronger, thicker materials. Ultimately, understanding these characteristics will help you select the right gauge of plastic roll that best fits your food packaging needs, ensuring safety and freshness from production to consumption.

How to Choose the Best Food Packaging Plastic Roll for Your Needs - Evaluating Thickness and Strength: How to Select the Right Gauge for Freshness and Safety

| Material Type | Gauge (mil) | Thickness (mm) | Strength (psi) | Freshness Duration (days) | Recommended Use |

|---|---|---|---|---|---|

| LDPE | 3 mil | 0.08 mm | 2000 psi | 5-7 days | Wraps for bread, baked goods |

| HDPE | 4 mil | 0.10 mm | 3000 psi | 7-10 days | Packaging for fruits, vegetables |

| PVC | 2 mil | 0.05 mm | 2500 psi | 3-5 days | Shrink wrap for meats |

| BOPP | 5 mil | 0.13 mm | 3500 psi | 10-14 days | Packaging for snacks, candies |

| PET | 6 mil | 0.15 mm | 4000 psi | 14-21 days | Containers for liquids, salads |

Cost Analysis: Balancing Quality and Budget in Food Packaging Choices

When choosing food packaging plastic rolls, it is crucial to consider both quality and cost. As consumers increasingly seek healthier and more sustainable food options, companies must adapt their packaging strategies to meet these demands without significantly inflating their budgets. The balance between maintaining high-quality materials and keeping costs manageable can be delicate. For businesses focusing on meal kits and food delivery services, the packaging not only serves a functional purpose but also communicates the brand's commitment to health and sustainability—a growing expectation among consumers.

Sustainability has become a driving force in the food packaging industry, prompting organizations to explore eco-friendly solutions. Despite the reliance on plastic, many brands are now prioritizing packaging that minimizes waste and environmental impact. This shift requires a thorough cost analysis to assess the viability of switching to more sustainable materials. As companies weigh the benefits of investing in higher-quality, eco-conscious packaging against budget constraints, they must also contemplate the long-term savings associated with reduced waste and enhanced consumer loyalty. Ultimately, the right packaging choice can significantly influence a company's bottom line while catering to the evolving preferences of today's health-minded consumers.

Regulatory Compliance: Navigating Food Safety Standards for Packaging Materials

When selecting food packaging plastic rolls, one of the foremost considerations is regulatory compliance related to food safety standards. Various jurisdictions have established stringent guidelines to ensure that packaging materials do not leach harmful chemicals into food products. Familiarizing yourself with these regulations is crucial, as non-compliance can lead to serious health risks for consumers and financial repercussions for manufacturers. Key standards often include guidelines from bodies like the FDA in the United States or EFSA in Europe, which outline permissible materials and testing protocols.

Understanding the specific requirements for your intended market is essential. This includes the types of food being packaged—whether they are dry, frozen, or require barrier protection against moisture and gases. Each category may have unique recommendations or prohibitions regarding material choice. Additionally, ensure that the selected plastic roll is certified for food contact, reflecting adherence to safety criteria. By carefully navigating these regulations, businesses can not only protect public health but also enhance their brand credibility, fostering consumer trust in their products.

Related Posts

-

Maximizing Freshness and Safety with Innovative Plastic Roll for Food Packaging Solutions

-

Innovative Trends in Food Packaging Roll Plastic Film Driving Sustainability and Reducing Waste

-

Innovative Trends in Food Packaging Plastic Roll Market Driving Sustainability and Efficiency

-

Unlocking the Advantages of Plastic Roll for Food Packaging that Elevate Shelf Life and Safety

-

5 Ways Best Food Packaging Plastic Roll Transforms Your Food Storage Strategy

-

Global Trends in Food Packaging: 2025 Market Insights & Case Studies on Best Food Packaging Roll Plastic Film

中国

中国