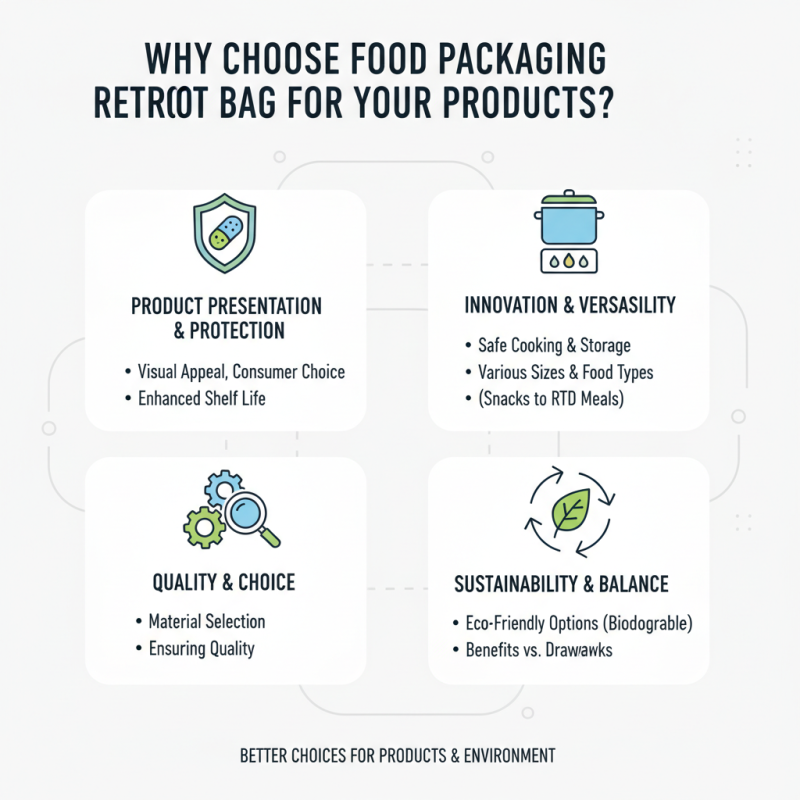

Why Choose Food Packaging Retort Bag for Your Products?

In today’s competitive market, product presentation matters. The appeal of your product can greatly influence consumer choice. This is where Food Packaging Retort Bag shines. These bags not only protect food but also enhance its shelf life. Their innovative design allows for safe cooking and storage.

Food Packaging Retort Bags come in various sizes. They can accommodate a wide range of food items. From snacks to ready-to-eat meals, these bags are highly versatile. Imagine a flavorful dish sealed in a bag that retains its taste. This is the beauty of retort packaging. Yet, the challenge lies in choosing the right materials and ensuring quality.

As you consider Food Packaging Retort Bags, reflect on sustainability. Are these bags eco-friendly? Many manufacturers are now focusing on biodegradable options. It’s essential to weigh the benefits against potential drawbacks. Finding the perfect balance may require some extra effort. This journey can lead to better choices for both your products and the environment.

Advantages of Using Retort Bags in Food Packaging

Retort bags offer several advantages in food packaging. These bags are designed to withstand high temperatures during the sterilization process. This ensures that food remains safe and free from harmful bacteria. The durability of these bags is impressive. They can endure the rigors of processing without tearing or leaking.

Another notable benefit is their lightweight nature. Retort bags reduce transportation costs, making them an eco-friendly option. They use less space, allowing for efficient storage. The clear windows on some bags enable consumers to see the product inside. This transparency builds trust.

However, while retort bags have many merits, they are not perfect. Their production can contribute to plastic waste concerns. Also, some may worry about the leaching of materials. It’s essential to consider these factors when choosing packaging solutions. Making informed choices about food packaging is crucial.

How Retort Bags Enhance Food Preservation and Shelf Life

Retort bags are gaining traction in the food industry for their remarkable ability to enhance food preservation. These flexible pouches are designed to withstand high temperatures during processing. The result is a significant reduction in spoilage. According to a report from the USDA, retort packaging can extend shelf life by up to 12-24 months compared to traditional methods.

One crucial factor is the barrier properties of retort bags. They limit the entry of oxygen and moisture, keeping food fresh longer. A study by the Food Packaging Forum revealed that these bags can decrease spoilage rates by approximately 30%. However, not all retort bags are equal. The choice of materials impacts their effectiveness. The right combination can greatly influence preservation capabilities.

Cost is another consideration. While initial investment may be higher, the extended shelf life and reduced waste can lead to savings. Yet, some manufacturers grapple with the transition. They may be hesitant to adopt a new packaging solution due to existing workflows. It’s essential to weigh the benefits against potential challenges. As the industry evolves, those who embrace innovative solutions like retort bags may gain a competitive edge.

The Manufacturing Process of Food Packaging Retort Bags

The manufacturing process of food packaging retort bags involves several crucial steps. It starts with selecting high-quality materials. Typically, multi-layer films are used. These can include polyester, foil, and polypropylene. Each layer serves a special purpose, such as durability and heat resistance.

Next, the printing process occurs. This stage is where vibrant graphics and labels are added. Companies often face challenges in ensuring print quality. Misalignment can happen, affecting branding. After printing, the material is cut into precise shapes. Proper measurements are necessary to prevent waste.

The final step is sealing. Retort bags need to withstand high temperatures during processing. Sealing methods must ensure no leaks. Testing for durability is essential, but some bags may fail. This inconsistency leads to customer dissatisfaction. Continuous improvement in the manufacturing process is vital to address these issues and enhance product reliability.

Comparative Analysis: Retort Bags vs. Traditional Packaging Methods

When comparing retort bags to traditional packaging methods, the differences become clear. Retort bags are made from advanced materials that withstand high temperatures. They provide a strong barrier against moisture and oxygen. This leads to a longer shelf life for food products, ensuring freshness. Traditional packaging often lacks this level of protection. Many products spoil quickly when sealed with conventional methods.

Cost should also be a consideration. Retort bags may have a higher upfront cost. However, they reduce waste due to fewer product returns from spoilage. While traditional packaging is often cheaper, it may lead to higher long-term costs. Sustainability is another point of reflection. In some cases, traditional methods can generate more waste. Retort bags are more efficient in their resource use. Still, some may argue about their recyclability.

The ease of use is striking with retort bags. They are lightweight and easy to store. This can make handling simpler, especially for distributors. Traditional packaging can be bulkier, leading to storage challenges. Yet, while retort bags have many advantages, they might not suit every product. Understanding the unique needs of your product is crucial. Balancing the benefits and limitations is key.

Why Choose Food Packaging Retort Bag for Your Products?

| Criteria | Retort Bags | Traditional Packaging |

|---|---|---|

| Shelf Life | 12-24 months | 6-12 months |

| Heat Resistance | Up to 121°C (250°F) | Up to 100°C (212°F) |

| Weight | Lightweight | Heavier |

| Cost | Cost-effective per unit | Higher costs for bulk |

| Environmental Impact | Recyclable options available | Less recyclable materials |

| Seal Integrity | High seal strength | Variable seal quality |

Sustainability and Environmental Impact of Retort Bag Packaging

Retort bags are gaining traction in the food industry for their sustainability. These bags are designed to withstand high temperatures, making them ideal for retort processing. Remarkably, they use less material compared to traditional packaging. A report from Smithers Pira indicates that flexible packaging reduces food waste by 15% due to its efficiency.

Using retort bags can significantly lower carbon footprints. According to the Flexible Packaging Association, flexible packaging reduces energy consumption by about 50% during production. This leads to fewer greenhouse gas emissions. However, some consumers still view plastic negatively. Change in perception is necessary for broader acceptance of these eco-friendly solutions.

While the advantages are clear, challenges remain. Recycling processes for retort bags are not as established as those for other materials. Only 9% of plastic waste is recycled globally, raising concerns. Companies should focus on improving recycling facilities. Finding sustainable ways to manage materials is critical for the future of packaging.

Related Posts

-

Evaluating Prepared Foods Packaging: Key Differences That Impact Your Supply Chain Choices

-

Unlocking Flavor: A Comprehensive Guide to the Best Sauce Curry Food Retort Pouch Specifications & Usage

-

Addressing Common Challenges with the Best Food Handle Pouch Retort Bag

-

Exploring Innovative Alternatives to Traditional Food Packaging Bags

-

How to Choose the Best Retort Pouches for Food Packing to Enhance Shelf Life and Quality

-

How to Choose the Best Retort Pouches for Food Packing Needs

中国

中国